The start of a new era.

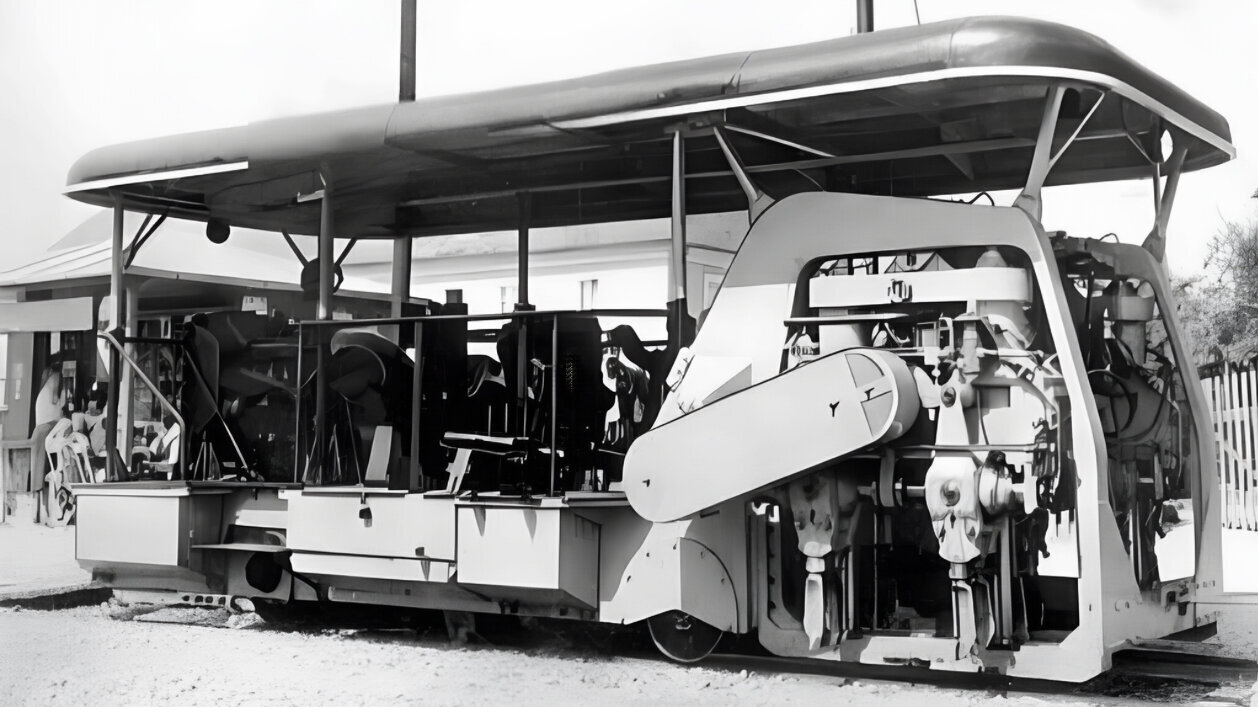

The first tamping machine.

The pride and joy of Walter Weiss. The VKR 03, the first tamping machine in Southern Germany and in use at LEONHARD WEISS since 1959. It marks the beginning of the mechanisation era at the company - and the many bold innovations that followed.

Tamping machines were not a completely new invention at the end of the 1950s, but they were still new on the German market. In 1931, August Scheuchzer from Switzerland developed a machine that used pressure and vibration to compact the ballast under the sleepers, creating a stable base for the tracks. While the ballast is being compacted, clamps hold the rails in the desired final position. This basic principle has not changed to this day, although the machine technology has been constantly adapted to new requirements and possibilities.

Wherever the LEONHARD WEISS tamping machine is used, it replaces one of the most laborious and time-consuming processes in track construction. Other machines will soon follow, including track levelling machines, ballast profiling machines, excavators, gantry cranes - and, of course, a few more tamping machines. The VKR 03 was joined by the VKR 05, the first track tamping machine with a lifting device, the VKR 06, a double-sleeper track tamping machine, the 07-32, a double-sleeper track levelling machine, and many more.

A lot has changed over the years. New machines have been developed to take over the manual work.

In the 1970s, technical innovations meant that a track could be rebuilt in a single night shift without affecting the timetable. A job that, before 1959, would have required many people, a lot of muscle, a lot of time, and often a lot of good ideas and a talent for improvisation because of the simple tools.

But even in the age of mechanised track construction, LEONHARD WEISS recognises the value of the good ideas that come from day-to-day work. What has always been a matter of course in the family business - listening, trying out, implementing - is being used as a competitive advantage. Suggestions from employees are systematically incorporated into technical developments.

In 2016, for example, a project team installed a fully hydraulic tamping unit - an absolute novelty on the market at the time. The idea was implemented by a project team in the company's own workshops in a short space of time. The result is a universal tamping machine that works more accurately and effectively, generates less noise and vibration, uses less energy and has low maintenance costs.

But it is not only the drivers who are consulted: the people who work on construction sites every day are also listened to when new tamping machine models are developed in cooperation with the manufacturers. Often it is small adjustments, such as improved seating positions, that make a big difference.

For a while I was still able to contribute a little to the tamping machine. We were allowed to have a say in what we wanted or what would be good for us. You should let those have a say who otherwise have no say at all.

“System 7 S7 PLS 16 4.0 - S” is the name of the new pride (since 2023) of the LEONHARD WEISS tamping machine fleet. It is one of the most modern universal tamping robots in the world and is affectionately known within the company as the 'EdelWeiss Express'. The tamping process is now fully automatic, reliable and accurate. The EdelWeiss Express also sets new standards in terms of climate friendliness. And it will not be the last innovation in track construction. After all, ideas are born where people work.